易切削鋼

易切削鋼是指具有優良切削加工性的鋼。 提高鋼的易切削性能主要是在鋼中單獨或組合添加易切削元素。

依易切削元素的不同,可分為硫易切削鋼、鉛易切削鋼、鈣易切削鋼和複合易切削鋼。

依用途不同,易切削鋼分為自動機械鋼、結構易切削鋼及特殊易切削鋼(耐熱鋼、不鏽鋼、工具鋼等)。 依易切削性能的不同,可分為一般易切削鋼、超級易切削鋼等。

電子郵件: [email protected]

電話: 0086-13788924073

| Country | Steel grade | Standard No. | Main chemical components % | ||||||||

| C | Si | Mn | p | S | Cr | Ni | Mo | Other | |||

| Japan | SUM23 | JIS G4804(2008) | 0.09 | 0.10-0.20 | 0.75~1.05 | 0.04~0.09 | 0.26~0.35 | ||||

| Korea | SUM23 | KS D3567(2002) | 0.09 | 0.10-0.20 | 0.75~1.05 | 0.04~0.09 | 0.26~0.35 | ||||

| India | 11C10S25 | IS 1570-3(2004) | 0.08~0.15 | 0.1 | 0.80~1.20 | 0. 06 | 0.20~0.30 | ||||

| Russia | A11 | TOCT1414(1975) | 0.07~0.15 | 0.1 | 0.80~1.20 | 0.06~0.12 | 0.15~0.25 | ||||

| Germany | 10S20/1.0721 | DIN EN 10087(1999) | 0.07~0.13 | 0.4 | 0.7 | 0. 060 | 0.15~0.25 | ||||

| France | S200 | NF A35-561(1992) | 0.13 | 0.08 | 0.70~1.20 | 0.11 | 0.20~0.27 | ||||

| Britain | 10S20 | BS EN 10087(1999) | 0.07~0.13 | 0.4 | 0.70~1.10 | 0.06 | 0.15~0.25 | ||||

| U.S.A | 1215/G12150 | ASTM A29/A29M(2005) | 0. 09 | 0.2 | 0.75~1.05 | 0.04~0.09 | 0.26~0.35 | ||||

| Japan | SUM24L | JIS G4804(2008) | 0.15 | 0.10~0.20 | 0.85~1.15 | 0.04~0.09 | 0.26~0.35 | Pb 0.10~0.30 | |||

| Korea | SUM24L | KS D3567(2002) | 0.15 | 0.10~0.20 | 0.85~1.15 | 0.04~0.09 | 0.26~0.35 | – | Pb 0.10~0.30 | ||

| Russia | AC14 | TOCT 1414(1975) | 0.10~0.17 | 0.12 | 1.00~1.30 | 0.1 | 0.15~0.30- | 0.25 | 0.25 | Pb 0.15~0.35 | |

| Germany | 11SMnPb30/1.0718 | DIN EN 10087(1999) | 0.14 | 0.05 | 0.90~1.30 | 0.11 | 0.27~0.33 | Pb 0.20~0.35 | |||

| France | 11SMnPb30 | NF EN 10087(1999) | 0.14 | 0. 05 | 0.90-1.30 | 0.11 | 0.27~0.33 | Pb 0.20~0.35 | |||

| S300Pb | NF A35-561(1992) | 0.15 | 0. 08 | 1.00-1.60 | 0.11 | 0. 30~0. 40 | Pb 0.20~0.30 | ||||

| Britain | 11SMnPb30 | NF EN 10087(1999) | 0.14 | 0. 05 | 0.90~1.30 | 0.11 | 0.27~0.33 | – | Pb 0.20~0.35 | ||

| U.S.A | 12L14/G12144 | ASTM A29/A29M(2005) | 0.15 | 0.2 | 0.85~1.15 | 0.04~0.09 | 0.26~0.35 | 一 | Pb 0.15-0.35 | ||

| Japan | SUM43 | JIS G4804(2008) | 0.40~0.48 | 0.15-0.35 | 1.35~1.65 | 0.04 | 0.24~0.33 | ||||

| Korea | SUM43 | KS D3567(2002) | 0.40-0.48 | 0.15~0.35 | 1.35~1.65 | 0.04 | 0. 24~0.33 | ||||

| India | 40C15S24 | IS 14698(1999) | 0.40-0.48 | 0.15~0.30 | 1.35~1.65 | 0. 04 | 0.24~0.33 | 一 | |||

| Germany | 44SMn28/1.0762 | DIN EN 10087 (1998) | 0.40-0.48 | 0.4 | 1.30-1.70 | 0.06 | 0.24~0.33 | – | |||

| France | 44SMn28 | NF EN 10087(1998) | 0.40~0.48 | 0. 40 | 1.30-1.70 | 0.06 | 0.24~0.33 | – | |||

| 45MF6 | NF A35-562(1992) | 0.41~0.48 | 0.10~0.40 | 1.30~1.70 | 0.04 | 0.24~0.32 | – | ||||

| Britain | 44SMn28 | BS EN 10087(1998) | 0.40~0.48 | 0.4 | 1.30~1.70 | 0.06 | 0.24~0.33 | – | |||

| U.S.A | 1144/G11440 | ASTM A29/A29M(2005) | 0.40-0.48 | 0.2 | 1.35~1.65 | 0.04 | 0.24~0.33 | ||||

| Japan | SUM32 | JIS G4804(2008) | 0.12~0.20 | 0.15~0.35 | 0.60~1.10 | 0.04 | 0. 10~0.20 | – | |||

| Korea | SUM32 | KS D3567(2002) | 0.12~0.20 | 0.15~0.35 | 0.60~1.10 | 0.04 | 0.10~0.20 | ||||

| India | 25C12S14 | IS 1570-3(2004) | 0.20-0.30 | 0.25 | 1.00~1.50 | 0.06 | 0.10~0.18 | – | |||

| Russia | A20 | TOCT 1414(1975) | 0.17-0.25 | 0.15~0.35 | 0.70~1.00 | 0.06 | 0. 08~0.15 | 0.25 | 0.25 | ||

| Germany | 15SMn13/1.0725 | DIN EN 10087(1999) | 0.12~0.28 | 0.4 | 0.90~1.30 | 0.06 | 0.08~0.18 | – | |||

| France | 15SMn13 | NF EN 10087(1999) | 0.12~0.28 | 0.4 | 0.90-1.30 | 0.06 | 0.08~0.18 | – | |||

| 18MF5 | NF A35-562(1992) | 0.16~0.22 | 0.10~0.40 | 1.10-1.50 | 0. 040 | 0.18~0.25 | – | ||||

| Britain | 15SMn13 | BS EN 10087(1999) | 0.12~0.28 | 0.4 | 0.90-1.30 | 0.06 | 0.08~0.18 | ||||

| U.S.A | 1117/G11170 | ASTM A29/A29M(2005) | 0.14-0.20 | 0. 20 | 1.00~1.30 | 0. 040 | 0. 08~0.13 | – | |||

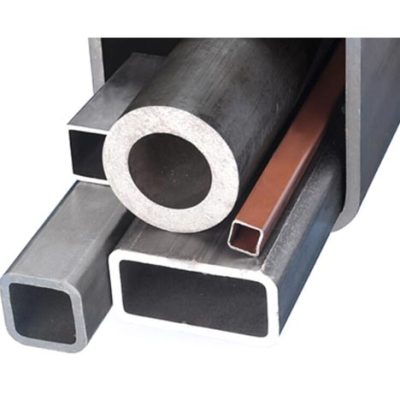

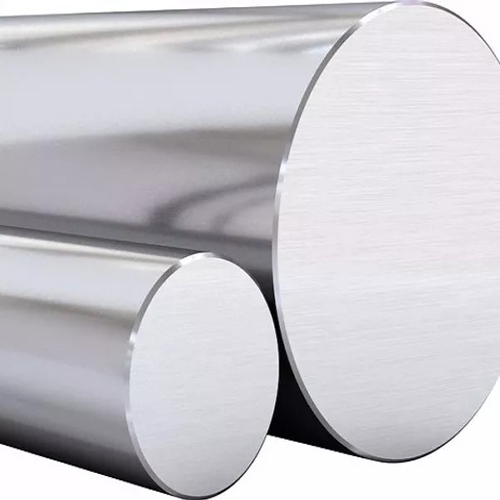

| Item | AISI 4140 1020 1045 Cold Drawn structure mild carbon/alloy forged bright cylinder steel round bar price for sale |

| Standard | GB/T 700-2006,GB/T 1591-94,JIS G3101-2004, ASTM A36/A36M-05,ASTM A242/A242M-04,ASTM A529/A529M-05, ASTM A572/A572M-06,EN 10025-2-2004 |

| Material | Q195,Q215 A,Q215 B,Q235 A,Q235 B,Q235 C, Q235D,Q275,Q275B,Q275C,Q275D,Q295,Q345,Q390,Q420, Q460, SS330,SS400,SS490,SS540,A36,1,GR.36,50(245),55(380),42(290), 60(415),65(450),S185(1.0035),S235JO(1.0114), S235JR(1.0038), S235J2(0.0117),S275JR(1.0044),S275JO(1.10143),S355JO(1.0553), E295(1.0050),E335(1.0060), S235J2W(1.861),S355J2W(1.8965),10#, 15#20# |

| Diameter | 4mm~800mm |

| Length | 1m,3m,5.8m,6m,12m or as required |

| Surface | polished,bright,black,coated,2b,ba,mirror,NO.4,8K |

| Package | Standard export seaworthy or as customers' requirements |

|

Application |

1.Mainly used in the manufacture of petroleum, chemical, gas separation and shipping container or other similar devices, such as all kinds of tower vessels, heat exchangers, torage tank and tank car, etc 2.Manufacture all kinds of stamping parts, construction and engineering structure and 3. Buildings and Bridges,Vehicles, towers and other structures. 4.Used as a floor, workshop escalator, working pedal, ship deck and car plate and so on 5.Make fixed boiler, boiler and other important hull attachments. 6.Pressure vessels, welding gas cylinder steel plate 7.Production of cutting tools, measuring tool and die |

我們還為客戶提供CNC精密加工服務,產品涉及能源,石化,鋼鐵,工程機械,塑膠,防治,液壓,醫療和食品等行業,歡迎發送圖紙詢價。