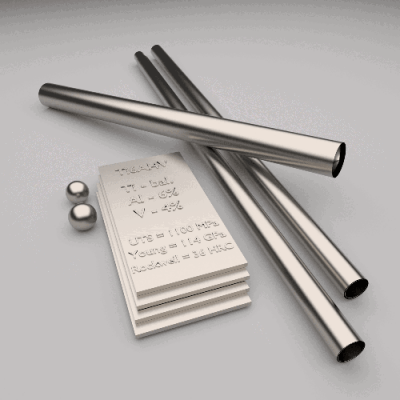

蒙乃爾合金

蒙乃爾合金又稱鎳合金,是以金屬鎳為基體,添加銅、鐵、錳等元素製成的合金。 蒙乃爾合金具有良好的耐腐蝕性,呈現銀白色,適用於邊線材質。

蒙乃爾400合金的組織為高強度單相固溶體,單相奧氏體組織。 是一種用量大、用途廣、綜合性能好的耐蝕合金。 該合金在氫氟酸和氟氣介質中具有優良的耐蝕性,在熱濃鹼溶液中也具有優良的耐蝕性。 同時也耐中性溶液、水、海水、大氣、有機化合物等的腐蝕。

長進經銷的產品包括管材、管材、管件、法蘭、薄板、帶材、板材、圓棒、扁棒、緊固件、鍛造件、六角鋼和線材等高溫合金。

電子郵件: [email protected]

電話: 0086-13788924073

● 任何類型和尺寸都可以自訂。

● 最小起訂量:10公斤起

● 付款方式:FOB 上海等,人民幣或美元

● 運輸方式:海運、鐵路、空運

● 包裝:強力包裝

| ASTM | UNS | W-Nr. | JIS | KS | Element | DIN EN/DIN | ||||

| Incoloy800 | N08800 | 1.4876 | NCF800/2B | NCF800 | GH20 | 0Cr20Ni32AlTi | X10NiCrAlTi32-20 | |||

| Incoloy800H | N08810 | 1.4958 | NCF800H | 1Cr20Ni32AlTi | X10NiCrAlTi32-20 | |||||

| Incoloy800HT | N08811 | 1.4959 | 0Cr25Ni35AlTi | |||||||

| Incoloy825 | N08825 | 2.4858 | NCF825 | NCF825 | 0Cr21Ni42Mo3Cu2Ti | NiCr21Mo | ||||

| Incoloy901 | ||||||||||

| Incoloy925 | N09925 | |||||||||

| Incoloy926 | N08926 | 1.4529 | ||||||||

| Inconel600 | N06600 | 2.4816 | NCF1B | NCF600 | GH600 | 1Cr15Ni75Fe8 | NiCr15Fe8 | |||

| Inconel601 | N06601 | 2.4851 | NCF601 | NCF601 | 1Cr23Ni60Fe13Al | NiCr23Fe | ||||

| Inconel625 | N06625 | 2.4856 | NCF625 | NCF625 | 0Cr20Ni65Mo10Nb4 | NiCr22Mo9Nb | ||||

| Inconel690 | N06690 | 2.4642 | 0Cr30Ni60Fe10 | NiCr29Fe | ||||||

| Inconel718 | N07718 | 2.4668 | GH169 | NiCr19Fe19Nb5Mo3 | ||||||

| Inconel725 | N07725 | |||||||||

| Inconel X-750 | N07750 | 2.4669 | NCF750 | GH145 | XCr15Fe7TiAl | |||||

| HC-276 | N10276 | 2.4819 | 00Cr15Ni60Mo16W5Fe5 | NiMo15Cr15W | ||||||

| HB | N10001 | 2.4800* | 0Ni65Mo28Fe5V | S-NiMo 30 | ||||||

| HB-2 | N10665 | 3.4617 | 00Ni70Mo28 | NiMo28 | ||||||

| HB-3 | N10675 | 2.4600* | NiMo29Cr | |||||||

| HC | N10002 | 2.4819 | 0Cr15Ni60Mo16W5Fe5 | NiMo16Cr15W | ||||||

| HC-4 | N06455 | 2.4610* | 00Cr16Ni65Mo16Ti | NiMo16Cr16Ti | ||||||

| HC-22 | N06022 | 2.4602 | NiMo21Cr14W | |||||||

| HC-2000 | N06200 | 2.4675 | NiCr23Mo16Cu | |||||||

| Hastelloy-X | N06002 | 2.4465 | ||||||||

| Monel400 | N04400 | 2.4360,2.4361 | ||||||||

| MonelK500 | N05500 | 2.4375 | ||||||||

| Monel401 | N04401 | |||||||||

| Monel404 | 2.4867 | |||||||||

| Ni 200 | N02200 | 2.4066 | ||||||||

| Ni 201 | N02201 | |||||||||

| Nitronic50 | S20910 | XM-19 | ||||||||

| Nitronic60 | S21800 | Alloy218 | ||||||||

| Alloy20 Cb-3 | N08020 | 2.4660* | Carpeter20Cb-3 | 0Cr20Ni35Mo3Cu4Nb | NiCr20CuMo | |||||

| Alloy31 | N08031 | 1.4562 | X1NiCrMoCu 32-28-7 | |||||||

| Alloy33 | N08033 | 1.4591 | X1NiCrMoCuN 33-32-1 | |||||||

| ASTM | UNS | W-Nr. | JIS | KS | Element | DIN EN/DIN | ||||

| Alloy20 Cb-3 | N08020 | 2.4660* | Carpeter20Cb-3 | 0Cr20Ni35Mo3Cu4Nb | NiCr20CuMo | |||||

| IncoloyA-286 | S66286 | 1.4980,1.4944 | SUH660 | |||||||

| Incoloy800 | NO8800 | 1.4876 | NCF800B | NCF2B | GH20 | 0Cr20Ni32AlTi | X2NiCrAlTi3220 | |||

| Nimonic75 | 2.4951 | |||||||||

| N06219 | 2.4855 | NiCr19Mo9Si | ||||||||

| HastelloyX | N06002 | 2.4613 | ||||||||

| Inconel600 | N06600 | 2.4816 | NCF1B | NCF600 | GH600 | 1Cr15Ni75Fe8 | NiCr15Fe8 | |||

| Inconel625 | N06625 | 2.4856 | NCF625 | NCF625 | NS3306 | 0Cr20Ni65Mo10Nb4 | NiCr22Mo9Nb | |||

| InconelX-750 | N07750 | 2.4669 | NCF750 | XCr15Fe7TiAl | ||||||

| Nimonic80A | N07080 | 2.4952 | ||||||||

| Inconel718 | N07718 | 2.4668 | GH4169 | |||||||

| Inconel725 | N07725 | |||||||||

| Incoloy925 | N09925 | |||||||||

| Inconel600 | N06600 | 2.4816 | NCF600 | NCF1B | 1Cr15Ni75Fe8 | LC-NiCr15Fe | ||||

| PB | ||||||||||

| Alloy4 | ||||||||||

| Alloy31 | N08031 | 1.4562 | ||||||||

| F15 | ||||||||||

| Invar36 | K93600 | 1.3912 | ||||||||

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex:2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy: Alloy 20/28/31 | |

| Hastelloy:HastelloyB/ -2/B-3/C22/C-4/S/C276/C-2000/G-35/G-30/X/N/g | |

| Hastelloy B/UNS N10001, Hastelloy B-2/UNS N10665/DIN W. Nr. 2.4617, Hastelloy C, Hastelloy C-4/UNS N06455/DIN W. Nr. 2.4610, Hastelloy C22/UNS N06022/DIN W. Nr. 2.4602, Hastelloy C276/UNS N10276/DIN W. Nr. 2.4819, Hastelloy X/UNS N06002/DIN W. Nr. 2.4665 |

|

| Haynes: Haynes 230/556/188 | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 |

|

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60 | |

| Nimonic: Nimonic 75/80A/90/A263 | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

We can provide customized services according to customer requirements

Commercially there are five types of Monel that are traded under ISO standards 6208 (plate, sheet, and strip), ISO 9725 (forgings), ISO 9723 (bars), ISO 9724 (wire), and the DIN 17751 (pipes and tubes). Those Monel grades are:

Monel 400 or alloy 400

Monel 401

Monel 404

Monel 405, and

Monel K-500

| Monel Grade/Trade Name | ASTM/AISI Alloy Type | UNS No. | %Ni | %Cu | %Fe | %Mn | %Al | %Ti | %Si |

| Monel 400 | B 127/ B 164 | N04400 | Min. 63 | 28-34 | Max 2.5 | Max 2.0 | Max 0.5 | ||

| Monel 401 | N04401 | Min. 63 | 28-34 | Max 2.5 | Max 2.0 | Max 0.5 | |||

| Monel 404 | N04404 | 52-57 | Remaining | Max 0.5 | Max 0.1 | Max 0.05 | Max 0.1 | ||

| Monel 405 | B 164 | N04405 | Min. 63 | 28-34 | Max 2.5 | Max 2.0 | Max 0.5 | ||

| Monel K500 | B 865 | N05500 | Min. 63 | 27-33 | Max 2.0 | Max 1.5 | 2.3-3.15 | 0.35-0.85 | Max 0.5 |

| Form | Condition | Tensile Strength (ksi) | Yield Strength (ksi) | % Elongation | Brinell hardness | Rockwell B Hardness | Tensile Strength (Mpa) | Yield Strength (Mpa) |

| Rod and Bar | Annealed | 75-90 | 25-50 | 60-35 | 110-149 | 60-80 | 517-620 | 172-345 |

| Rod and Bar | Hot-Finished (except Hexagons over 2 1/8 inches and Angles) |

80-110 | 40-100 | 60-30 | 140-241 | 75-100 | 552-758 | 276-690 |

| Rod and Bar | Hot-Finished Hexagons over 2 1/8 inches and Angles |

75-100 | 30-55 | 50-30 | 130-184 | 72-90 | 517-690 | 207-379 |

| Rod and Bar | Cold-Drawn, Stress-Relieved | 84-120 | 55-100 | 40-22 | 160-225 | 85-20C | 579-827 | 379-690 |

| Plate | Hot Rolled | 75-95 | 40-75 | 45-30 | 125-215 | 70-96 | 517-655 | 276-517 |

| Plate | Hot Rolled, Annealed | 70-85 | 28-50 | 50-35 | 110-140 | 60-76 | 482-586 | 193-345 |

| Sheet | Annealed | 70-85 | 30-45 | 45-35 | 65-80 | 482-586 | 207-310 | |

| Sheet | Cold Rolled, hard | 100-120 | 90-110 | 15-02 | Min. 93 | 690-827 | 621-758 | |

| Cold Rolled Strip | Annealed | 70-85 | 25-45 | 55-35 | Max. 68 | 482-586 | 172-310 | |

| Cold Rolled Strip | Spring Temper | 100-140 | 90-130 | 15-02 | Min. 98 | 690-965 | 621-896 | |

| Seamless pipe and tube | Cold Drawn, Annealed | 70-85 | 25-45 | 50-35 | Max 75 | 482-586 | 172-310 | |

| Seamless pipe and tube | Cold Drawn, Stress Relieved | 100-140 | 55-100 | 35-15 | 85-100 | 586-827 | 379-690 | |

| Cold Drawn Wire | Annealed | 70-95 | 30-55 | 45-25 | 482-655 | 207-379 |

我們還為客戶提供CNC精密加工服務,產品涉及能源,石化,鋼鐵,工程機械,塑膠,防治,液壓,醫療和食品等行業,歡迎發送圖紙詢價。