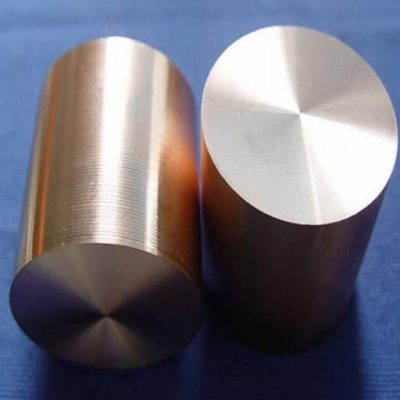

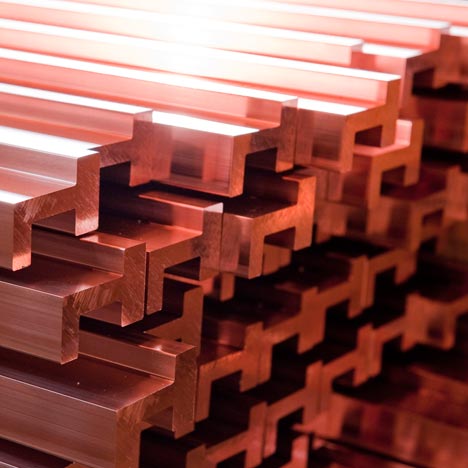

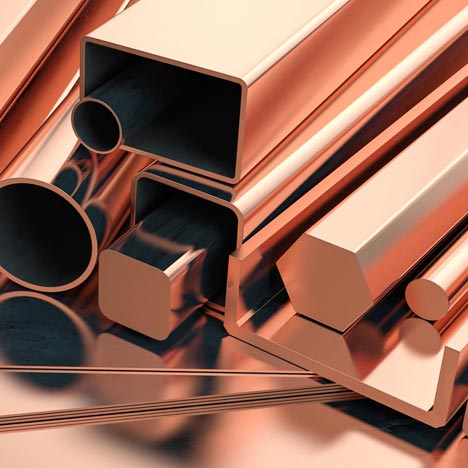

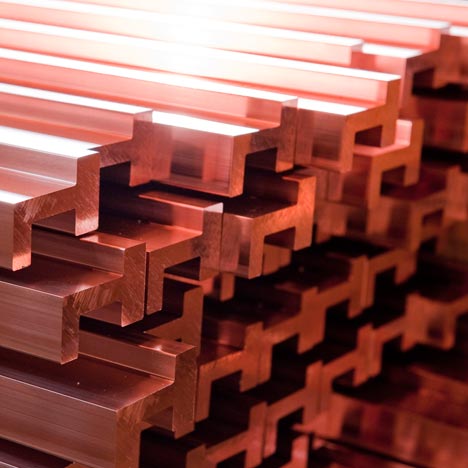

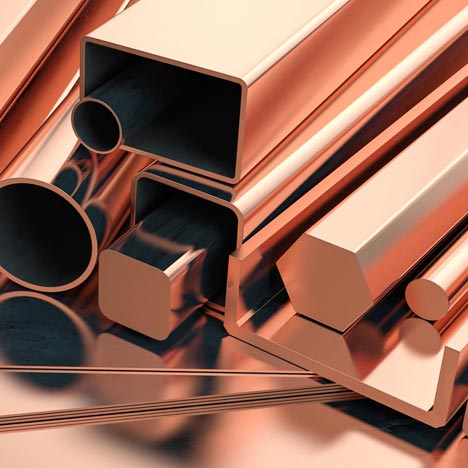

銅質型材

型材是根據建築設計的要求,不製成平面形狀而是製成各種形狀,或進行各種表面雕刻的材料。 長期以來,塑膠型材擠出加工,在我國塑膠加工業中一直是比較薄弱的一類,採用單螺桿擠出機、擠出模頭以低速率(1 m/min左右)生產比較簡單的型材個人資料。

本公司型材品質可靠,歡迎訂購。

電子郵件: [email protected]

電話: 0086-13788924073

1. 非常好的表現。 從銅型材具有強度高、韌性好、延展性好這些特點我們可以看出,這種型材具有非常好的表現這方面的應用優勢,可以依靠這方面的應用優勢,有效抵禦各種外在因素的不利影響。

2. 結構穩定。 具有強度高、韌性好這些特點,銅型材的整體結構必須非常穩定,有了這樣的結構,型材才能達到穩定可靠的應用,得到正常的功能。

3. 使用壽命長。 銅型材具有豐富的特性,並且具有許多的性能優勢,在應用中可以有效避免各種外部因素的不利影響,這樣的型材必然具有較長的使用壽命。

| Grade list of copper and copper alloys by country | |||||||

| Classification | China | Germany | America | Japan | England | Europe | International |

| oxygen free copper | TU1 | 2.0076 | C10200 | C1020R | C103 | ||

| TU2 | Cu-OF-H110 | C11000 | c1011 | C101 | |||

| Vacuum oxygen free copper | E-Cu58 | TU00 | c1020 | 6N | |||

| high purity | copper-OFE | c10500 | c10700 | ||||

| Silver copper | TAg 0.1 | CuAg 0.1 | C10400 | C1040 | CuAg 0.1 | ||

| brass | H90 | CuZn10 | C22000 | C2200 | CZ101 | CuZn10 | CW501L |

| H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 | CW505L | |

| H68 | C26200 | C2620 | CuZn33 | CW506L | |||

| H65 | CuZn35 | C27000 | C2700 | CZ107 | CuZn36 | CW507L | |

| H63 | CuZn37 | C27200 | C2720 | CZ108 | CuZn37 | CW508L | |

| H62 | CuZn40 | C28000 | C2800 | CZ109 | CW509L | ||

| bronze | QSn4-0.3 | CuSn4 | C51100 | C5111 | PB101 | CuSn4 | CW450K |

| CuSn5 | C51000 | C5101 | CuSn5 | CW451K | |||

| QSn6.5-0.1 | CuSn6 | C51900 | C5191 | PB103 | CuSn6 | CW452K | |

| QSn8-0.3 | CuSn8 | C52100 | C5210 | CuSn8 | CW453K | ||

| QSn6.5-0.4 | |||||||

| copper-nickel | BZn18-18 | CuNi18Zn20 | C75200 | C7521 | NS106 | CuNi18Zn20 | |

| BZn18-26 | CuNi18Zn27 | C77000 | C7701 | NS107 | CuNi18Zn27 | CW410J | |

| BZn15-20 | C7541 | CW409J | |||||

| BZn18-10 | C7350 | ||||||

| pure copper | TU2 | OF-Cu58 | C10100 | C1011 | C101 | CW008A | copper oxide |

| T2 | SW——copper | C11000 | C1100 | C101 | copper - FRHC | ||

| TP2 | SF-Cu | C12200 | C1220 | C106 | CW024A | copper - DHP | |

| TP1 | SW-copper | C12000 | C1201 | CW023A | copper DLP | ||

According to EN 13601

| Alloy | Temper | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness(HB) | Conductivity(MS/m) |

| Cu-ETP | D (Hard as drawn) | - | - | - | - | 56 min |

| H035 | - | - | - | 35 -65 | 58 min | |

| R200 | 200 min | 120 max | 25 min | - | 58 min | |

| H065 | - | - | - | 65 -90 | 57 min | |

| R230 | 230 min | 160 min | - | - | 57 min | |

| R250 | 250 min | 200 min | 8 min | - | 57 min | |

| H085 | - | - | - | 85 -110 | 57 min | |

| R300 | 300 min | 260 min | 5 min | - | 57 min |

According to ASTM B 187

| Alloy | Temper | Rod & Bar Strength(mm) | Elongation(%) | Hardness(HV) | Conductivity(MS/m) |

| Cu-ETP | O60 | All sizes | 25 min | 57 max | 58 min |

| H04 | For rod: Up to 10 incl. | 12 min | - | 56 min | |

| Over 10 to 25 incl. | 12 min | 89 min | 56 min | ||

| Over 25 to 50 incl. | 15 min | 83 min | 56 min | ||

| Over 50 to 75 incl. | 15 min | 71 min | 57 min | ||

| Over 75 | 15 min | - | - | ||

| For bar: Up to 10 incl. thickness and up to 110 incl. in width | 10 min | 89 min | 56 min | ||

| All other sizes | 15 min | 71 min | 57 min |

According to JIS H 3250

| Alloy | Temper | Rod & Bar Strength(mm) | Tensile Strength(MPa) | Elongation(%) | Conductivity(MS/m) |

| Cu-ETP | O | 6 or over up to and incl. 10 | 195 min | 30 min | 58 min |

| ½ H | 6 or over up to and incl. 25 | 245 min | 15 min | 57 min | |

| over 25 up to and incl. 50 | 225 min | 20 min | 57 min | ||

| over 50 up to and incl. 75 | 215 min | 25 min | 57 min | ||

| H | 6 or over up to and incl. 25 | 275 min | - | 56 min |

According to JIS H 3140

| Alloy | Temper | Rod & Bar Strength(mm) | Tensile Strength(MPa) | Elongation(%) | Conductivity(MS/m) |

| Cu-ETP | O | 2.0 or over up to and incl. 30 | 195 min | 35 min | 58 min |

| ½ H | 2.0 or over up to and incl. 30 | 215-275 | 25 min | 57 min | |

| ¼ H | 2.0 or over up to and incl. 20 | 245-315 | 15 min | 57 min | |

| H | 2.0 or over up to and incl. 10 | 275 min | - | 56 min |

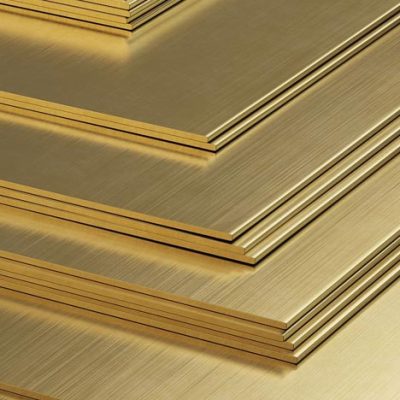

主要用於製作發電機、母線、電纜、開關櫃、變壓器等電氣設備、太陽能加熱裝置的熱交換器、管路、平板集熱器等。

我們還為客戶提供CNC精密加工服務,產品涉及能源,石化,鋼鐵,工程機械,塑膠,防治,液壓,醫療和食品等行業,歡迎發送圖紙詢價。