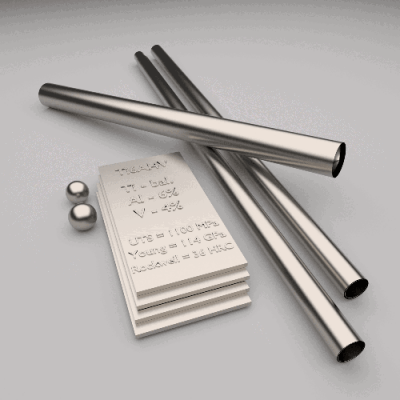

英高鎳合金

鉻鎳鐵合金是以鎳為主要成分的奧氏體高溫合金,具有良好的高溫耐蝕性和抗氧化性,冷熱加工和焊接性能優異,多用於航空、化工、造紙工業等領域。

常用的有因科內爾600、因科內爾601、因科內爾625、因科內爾617、因科內爾718、因科內爾x750等。

長進金屬提供各種形式的鎳合金鉻鎳鐵合金,包括:棒材、線材、板材、板材、鍛件、管件、法蘭、無縫管和焊管、無縫管和焊管、焊條。

電子郵件: [email protected]

電話: 0086-13788924073

● 任何類型和尺寸都可以自訂。

● 最小起訂量:10公斤起

● 付款方式:FOB 上海等,人民幣或美元

● 運輸方式:海運、鐵路、空運

● 包裝:強力包裝

無論您需要切割鋼坯還是切割成一定長度的標準棒材,我們的加工團隊都會為您提供符合您確切尺寸要求的材料。 我們在同一屋簷下執行這些操作,使我們成為滿足您所有先進工程材料需求的單一供應來源。

- Inconel 718, Inconel 617, Inconel 601, Inconel 600, InconelX-750

- UNS N06601, UNS N06600, Inconel 625, Inconel 686, Inconel 690, Inconel 713C

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex:2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy: Alloy 20/28/31 | |

| Hastelloy:HastelloyB/ -2/B-3/C22/C-4/S/C276/C-2000/G-35/G-30/X/N/g | |

| Hastelloy B/UNS N10001, Hastelloy B-2/UNS N10665/DIN W. Nr. 2.4617, Hastelloy C, Hastelloy C-4/UNS N06455/DIN W. Nr. 2.4610, Hastelloy C22/UNS N06022/DIN W. Nr. 2.4602, Hastelloy C276/UNS N10276/DIN W. Nr. 2.4819, Hastelloy X/UNS N06002/DIN W. Nr. 2.4665 |

|

| Haynes: Haynes 230/556/188 | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 |

|

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60 | |

| Nimonic: Nimonic 75/80A/90/A263 | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

We can provide customized services according to customer requirements

| ASTM | UNS | W-Nr. | JIS | KS | Element | DIN EN/DIN | ||||

| Incoloy800 | N08800 | 1.4876 | NCF800/2B | NCF800 | GH20 | 0Cr20Ni32AlTi | X10NiCrAlTi32-20 | |||

| Incoloy800H | N08810 | 1.4958 | NCF800H | 1Cr20Ni32AlTi | X10NiCrAlTi32-20 | |||||

| Incoloy800HT | N08811 | 1.4959 | 0Cr25Ni35AlTi | |||||||

| Incoloy825 | N08825 | 2.4858 | NCF825 | NCF825 | 0Cr21Ni42Mo3Cu2Ti | NiCr21Mo | ||||

| Incoloy901 | ||||||||||

| Incoloy925 | N09925 | |||||||||

| Incoloy926 | N08926 | 1.4529 | ||||||||

| Inconel600 | N06600 | 2.4816 | NCF1B | NCF600 | GH600 | 1Cr15Ni75Fe8 | NiCr15Fe8 | |||

| Inconel601 | N06601 | 2.4851 | NCF601 | NCF601 | 1Cr23Ni60Fe13Al | NiCr23Fe | ||||

| Inconel625 | N06625 | 2.4856 | NCF625 | NCF625 | 0Cr20Ni65Mo10Nb4 | NiCr22Mo9Nb | ||||

| Inconel690 | N06690 | 2.4642 | 0Cr30Ni60Fe10 | NiCr29Fe | ||||||

| Inconel718 | N07718 | 2.4668 | GH169 | NiCr19Fe19Nb5Mo3 | ||||||

| Inconel725 | N07725 | |||||||||

| Inconel X-750 | N07750 | 2.4669 | NCF750 | GH145 | XCr15Fe7TiAl | |||||

| HC-276 | N10276 | 2.4819 | 00Cr15Ni60Mo16W5Fe5 | NiMo15Cr15W | ||||||

| HB | N10001 | 2.4800* | 0Ni65Mo28Fe5V | S-NiMo 30 | ||||||

| HB-2 | N10665 | 3.4617 | 00Ni70Mo28 | NiMo28 | ||||||

| HB-3 | N10675 | 2.4600* | NiMo29Cr | |||||||

| HC | N10002 | 2.4819 | 0Cr15Ni60Mo16W5Fe5 | NiMo16Cr15W | ||||||

| HC-4 | N06455 | 2.4610* | 00Cr16Ni65Mo16Ti | NiMo16Cr16Ti | ||||||

| HC-22 | N06022 | 2.4602 | NiMo21Cr14W | |||||||

| HC-2000 | N06200 | 2.4675 | NiCr23Mo16Cu | |||||||

| Hastelloy-X | N06002 | 2.4465 | ||||||||

| Monel400 | N04400 | 2.4360,2.4361 | ||||||||

| MonelK500 | N05500 | 2.4375 | ||||||||

| Monel401 | N04401 | |||||||||

| Monel404 | 2.4867 | |||||||||

| Ni 200 | N02200 | 2.4066 | ||||||||

| Ni 201 | N02201 | |||||||||

| Nitronic50 | S20910 | XM-19 | ||||||||

| Nitronic60 | S21800 | Alloy218 | ||||||||

| Alloy20 Cb-3 | N08020 | 2.4660* | Carpeter20Cb-3 | 0Cr20Ni35Mo3Cu4Nb | NiCr20CuMo | |||||

| Alloy31 | N08031 | 1.4562 | X1NiCrMoCu 32-28-7 | |||||||

| Alloy33 | N08033 | 1.4591 | X1NiCrMoCuN 33-32-1 | |||||||

| ASTM | UNS | W-Nr. | JIS | KS | Element | DIN EN/DIN | ||||

| Alloy20 Cb-3 | N08020 | 2.4660* | Carpeter20Cb-3 | 0Cr20Ni35Mo3Cu4Nb | NiCr20CuMo | |||||

| IncoloyA-286 | S66286 | 1.4980,1.4944 | SUH660 | |||||||

| Incoloy800 | NO8800 | 1.4876 | NCF800B | NCF2B | GH20 | 0Cr20Ni32AlTi | X2NiCrAlTi3220 | |||

| Nimonic75 | 2.4951 | |||||||||

| N06219 | 2.4855 | NiCr19Mo9Si | ||||||||

| HastelloyX | N06002 | 2.4613 | ||||||||

| Inconel600 | N06600 | 2.4816 | NCF1B | NCF600 | GH600 | 1Cr15Ni75Fe8 | NiCr15Fe8 | |||

| Inconel625 | N06625 | 2.4856 | NCF625 | NCF625 | NS3306 | 0Cr20Ni65Mo10Nb4 | NiCr22Mo9Nb | |||

| InconelX-750 | N07750 | 2.4669 | NCF750 | XCr15Fe7TiAl | ||||||

| Nimonic80A | N07080 | 2.4952 | ||||||||

| Inconel718 | N07718 | 2.4668 | GH4169 | |||||||

| Inconel725 | N07725 | |||||||||

| Incoloy925 | N09925 | |||||||||

| Inconel600 | N06600 | 2.4816 | NCF600 | NCF1B | 1Cr15Ni75Fe8 | LC-NiCr15Fe | ||||

| PB | ||||||||||

| Alloy4 | ||||||||||

| Alloy31 | N08031 | 1.4562 | ||||||||

| F15 | ||||||||||

| Invar36 | K93600 | 1.3912 | ||||||||

| Inconel | Element, proportion by mass (%) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Fe | Mo | Nb &Ta | Co | Mn | Cu | Al | Ti | Si | C | S | P | B | |

| 600 | ≥72.0 | 14.0–17.0 | 6.0–10.0 | — | ≤1.0 | ≤0.5 | ≤0.5 | ≤0.15 | ≤0.015 | ||||||

| 617 | 44.2–61.0 | 20.0–24.0 | ≤3.0 | 8.0–10.0 | 10.0–15.0 | ≤0.5 | ≤0.5 | 0.8–1.5 | ≤0.6 | ≤0.5 | 0.05–0.15 | ≤0.015 | ≤0.015 | ≤0.006 | |

| 625 | ≥58.0 | 20.0–23.0 | ≤5.0 | 8.0–10.0 | 3.15–4.15 | ≤1.0 | ≤0.5 | ≤0.4 | ≤0.4 | ≤0.5 | ≤0.1 | ≤0.015 | ≤0.015 | ||

| 690 | ≥58 | 27–31 | 7–11 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.05 | ≤0.015 | |||||||

| Nuclear grade 690 | ≥58 | 28–31 | 7–11 | ≤0.10 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.04 | ≤0.015 | ||||||

| 718 | 50.0–55.0 | 17.0–21.0 | Balance | 2.8–3.3 | 4.75–5.5 | ≤1.0 | ≤0.35 | ≤0.3 | 0.2–0.8 | 0.65–1.15 | ≤0.35 | ≤0.08 | ≤0.015 | ≤0.015 | ≤0.006 |

| X-750 | ≥70.0 | 14.0–17.0 | 5.0–9.0 | 0.7–1.2 | ≤1.0 | ≤1.0 | ≤0.5 | 0.4–1.0 | 2.25–2.75 | ≤0.5 | ≤0.08 | ≤0.01 | |||

航空、航太發動機中各種靜止和旋轉零件的製造,如盤、環、殼體、軸、葉片、緊固件、彈性元件、導氣管、密封元件等以及焊接結構件; 各種彈性元件和框架的製造工業應用; 製造用於石油和化學工業的零件和其他零件。

| INCONEL GRADES | DESCRIPTION | APPLICATION |

|---|---|---|

| Inconel 600 | solid solution strengthen | aerospace, chemical industry, pulp and paper industry, food processing, heat treating industry, nuclear engineering, gas turbine components |

| Inconel 601 | nickel-chromium alloy has good temperature strength, and oxidation resistance | chemical processing, heat treating industry, aerospace, power generation, radiant tubes, steam superheater tube supports, etc |

| Inconel 625 | has good weldability, acid resistant | aerospace, aircraft ducting systems, jet engine exhaust systems, specialized seawater equipment, engine thrust-reverser systems, chemical process equipment |

| Inconel 690 | has low resistivity, has lower cobalt content for nuclear applications | high-temperature burners, duct work, petrochemical heaters, furnaces |

| Inconel 718 | has good weldability, gamma double prime strengthened | nuclear reactors, aerospace, chemical processing, pollution-control equipment, gas turbine parts, liquid fuel rocket motor components |

| Inconel 751 | has increased aluminum content for an improved rupture | exhaust valves like on heavy-duty diesel engines |

| Inconel 792 | has increased aluminum content, has high-temperature corrosion resistance | gas turbines |

| Inconel 903 | nickel-cobalt alloy has high oxidation resistance and temperature strength | gas turbine and hot section components |

| Inconel 939 | has increased weldability, gamma prime strengthened | used for high-heat environments |

我們還為客戶提供CNC精密加工服務,產品涉及能源,石化,鋼鐵,工程機械,塑膠,防治,液壓,醫療和食品等行業,歡迎發送圖紙詢價。